Lean Project Management

When is it necessary to use Lean project management?

Browse topics

All project managers strive to remove waste and boost productivity, which generally means increasing output while using fewer resources. If you care about increasing the productivity of your business or are interested in effective product management strategies, you might want to try out Lean project management. Here we’ll discuss what it is, define its forms and benefits, and describe its application.

What Does Lean Mean in Project Management?

Lean project management implies using Lean manufacturing principles for management. The key goal of Lean PM is to maximize value and minimize waste.

The principles of Lean manufacturing were created by well-known Toyota in the 1950s. They were also actively applied in the 1970s to combat the energy crisis. As a term, it appeared in the late 1980s.

Lean project management aims to reduce the activities that consume resources without providing additional value, overuse of employees or equipment, and decreasing efficiency and productivity in the long term.

Lean PM benefits

Businesses that use Lean project management can expect:

- Decreased overall costs

- Lower inventory and storage costs

- Reduced lead times

- Better quality

- Accelerated efficiency and productivity

- Higher customer satisfaction

What Is the Difference Between Traditional and Lean Project Management Processes?

Lean project management is not as established as Lean manufacturing, but comparing these two process cycles will let you understand the difference between the Waterfall (traditional) model of project management lifecycle and the Lean counterpart.

Lean PM is based on iterative processes. In traditional project management, many activities are going on at once, and the product is delivered in the end.

Lean project management is aimed to deliver value to the audience continuously and quickly.

Agile PM vs Lean PM

Lean is often used as a synonym of Agile. It is harmless but isn’t necessarily correct. Both methods describe a way of approaching work with a focus on value. However, they recommend somewhat different ways of achieving it. Another differentiator is the scale, to which the two methods can extend in an organization.

Lean originates from manufacturing practices. It is more about a systematic approach, an organization-wide method of streamlining how value is created.

The roots of Agile come from software engineering. The methodology focuses on producing high value fast, but through applying short iterations and focusing on team collaboration.

Both Agile and Lean help companies and teams to work better and deliver higher quality to their clients. It’s common for companies to take advantage of both methods so as to get the best possible results.

What Are the 5 Principles of Lean?

The essence of the Lean approach lies in some specific principles. Let’s list them out and consider their essentials.

Principle 1. Loss exception

It is one of the fundamentals of Lean project management. A loss in Lean means any element that stops bringing significance or value for users. Lean is closely related to the user needs and preferences, which in turn has a real impact on development. Additionally, losses include the following cases:

- development hold-ups that are often caused by unclear project requirements.

- implementation of excessive functionality into the project.

- extra time waste through bureaucracy and solving different business issues with other people.

Principle 2. Fast speed of project delivery

This Lean principle follows logically from the first principle. Thanks to the lack of losses and saving resources, developers cope with the work on the project faster.

Short work periods impact this velocity: each iteration allows teams to make up a specific product version with its viable functions. The short-term and frequent releases let customers be the owners of a finished product, which makes the development process better and faster.

Principle 3. Focus on continuous learning and team motivation

Lean is more than just a working practice. It combines the most valuable resource – people and continuous learning. That’s why it is crucial to provide people with a comfortable environment for work, creativity, and personal fulfillment. A motivated working team will definitely lead to victory.

The easiest way to implement it is constant education to get new working experience and using many new practices. Project managers should constantly care about reading professional books, improving their qualifications, visiting related conferences or seminars, and in general, being the leaders of the project development process.

Other team members should be also responsible for their knowledge base and professional skills.

Principle 4. A holistic vision of the work

Many people think that this Lean principle looks controversial because every person understands integrity in his or her own way and perceives the effectiveness of the approach individually.

However, the holistic vision in Lean lies in the integration of relationships between the development team and involved specialists. This allows them to offer project solutions in a unified manner and make the right calls during the development process.

Principle 5. Last-minute decisions

Let’s define this principle as the unique feature of the Lean approach. We all usually tend to make preliminary predictions and assumptions that relate to some functional or tech solutions of the project. However, the Lean methodology does not accept this approach. Instead of possible expectations and approximate estimates, the final decision on any project structure implementation is made during the actual work on it. Despite the real reasonability of this Lean principle, not many organizations are ready to use it.

Lean Project Management Tools

Lean project managers rely on some powerful tools that help them to prioritize and manage work: A3 Thinking, Value Stream Mapping, and Kanban.

A3 thinking

This is an incredibly valuable tool in the Lean project management philosophy. This method is a structured problem-solving approach that promotes intentional continuous improvement.

A3 thinking is the way of defining, analyzing, and developing hypotheses around a problem. It is called A3 as every single idea should be small and manageable enough to fit onto one piece of A3 paper. This approach is based upon the PDCA (Plan-Do-Check-Act) model. It encourages companies to accurately define every problem and develop a hypothesis to test to resolve it.

Value stream mapping

This tool was used by Toyota to determine and optimize the steps involved in getting a product or project from start to finish. Value stream mapping identifies the current and future states of a workflow. It also defines all activities that enter into and out of the workflow.

Flow visualizing gives teams a clear understanding of how value travels. Defining the parts of the value stream is essential for Lean transformation as it can surface inefficiencies blocking the flow of value to the customer.

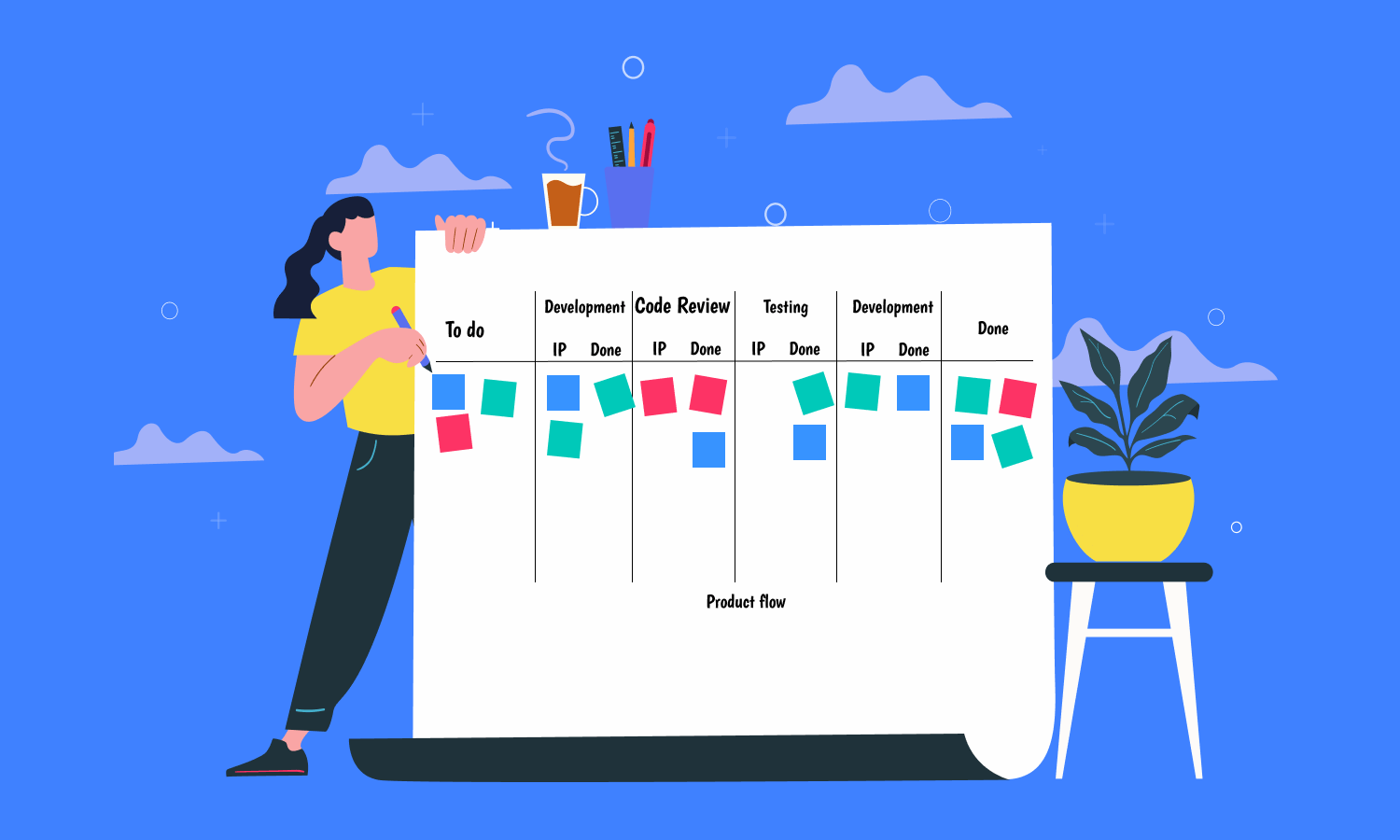

Kanban

This is a well-known method of workflow management that allows teams to visualize, prioritize, and improve upon their work. Kanban helps project teams to use the power of visual information by working with boards and cards.

Handy online Kanban boards help managers to stay up to date on all relevant work information at a glance. And there is no need to interrupt the team for information about status, bottlenecks, and blockers.

How Lean Helps to Prevent Fatal Project Mistakes

Lean principles may help project managers to avoid or mitigate situations that might otherwise lead to project failures.

Here is the list of common project pitfalls that Lean thinking can help to avoid.

- Failing to establish customer value: When you understand the value your company offers to clients, you can more clearly set project requirements, price the project, and revise workstreams.

- Scope creep: When the value of your project increases but corresponding changes in budgeting don’t account for the increased value.

- Failing to define the value stream: If you do not define the value stream with the aim to optimize it, non-value-creating activities may continue to strain your project budget and extend the project schedule.

- Lack of a communication plan. Without effective communication, your project runs the risk of wasting time and resources on time-consuming approvals and value mismatches.

- Lack of stakeholder commitment. Stakeholders who are not fully committed to the project may be less likely to extend support when a project needs it.

Conclusion

By following the core Lean principles listed above, you are implementing Lean project management and it means that your clients will likely thank you for these efforts.

Satisfied clients are a clear mark of an effective company and successful processes.

Adhering to Lean project management ideas will help you to achieve shorter lead times, cost reduction, improved quality, customer satisfaction, as well as better process efficiency.