Kanban As a Method of Inventory Management

If you are a software developer, you definitely know Kanban as a methodology that allows you to run your projects fast and efficiently. Perhaps you even use special Kanban project management tools. They are extremely convenient if your team prefers to use this Agile methodology. However, Kanban can be applied not only to software development. It is much wider than a software developer can imagine. In this article we will tell you about Kanban inventory systems and the main aspects of their functioning.

To realize what a Kanban inventory system is, it is necessary to refer to the history of this method. Initially, Kanban originated in Japan in 1940-s. It was invented by the specialists of Toyota Corporation to optimize the manufacturing process. At that time the famous Japanese motor corporation had lots of problems with the delivery of its production. The final products often didn’t meet the requirements of the customers. That is why the company suffered from failures in the competitive struggle. Toyota needed to improve its system of product delivery and the quality of its production. Kanban was invented to achieve this goal. The word “Kanban” can be translated from Japanese as a billboard or a task board. The initial idea of Kanban inventors was simple. They wanted to create a system that allows to track the workflow from its very beginning till its end and to visualize it. Initially that was made by using a special task board. It represented all stages of work that one task should pass before the delivery of the final product to the customer.

Consideration of the customer’s demands was another principle of the Kanban manufacturing strategy. The managers of the enterprise must know the demands of the customers. There are two main criteria of these demands. The first criterion answers the question: “What does the customer want to get?”, and the second one – the question: “When does the customer want to get it?” The implementation of Kanban approach allowed Toyota to become one of the largest motor corporations in the world.

As we see, Kanban is actually a method of inventory management. Its main idea is to manage the process of manufacturing by controlling the amounts of supplied raw material and the terms of final product delivery. As we have already mentioned, the employees of Kanban-based enterprises use the criterion of customer acceptance to manage these processes.

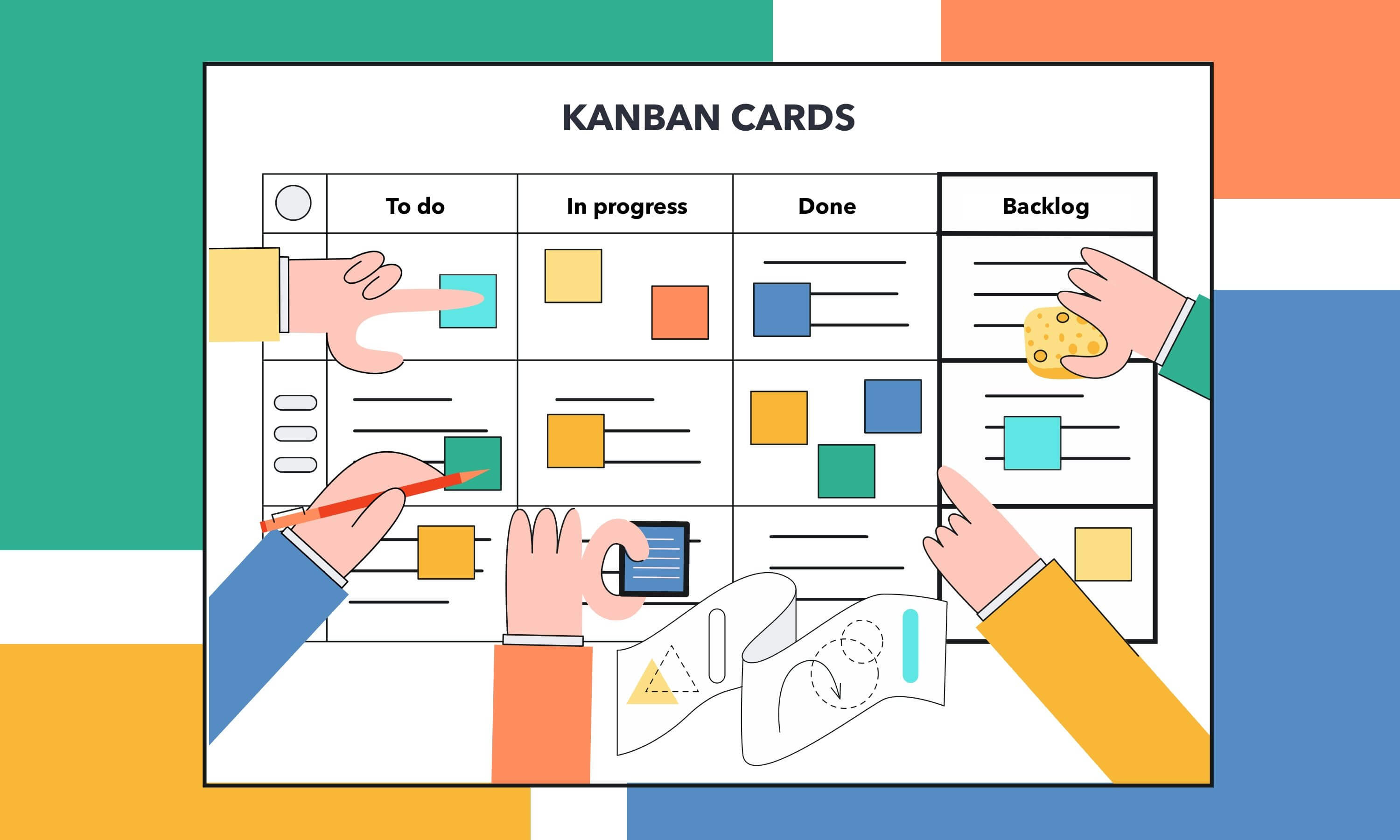

Kanban inventory control is usually conducted with the use of typical Kanban methods like limitation of work in progress and visualization of workflow. Modern corporations that prefer to use Kanban methodology have Kanban task boards just like 60 years ago. The only difference is the ability to make these boards digital. Kanban inventory cards are placed on the task board in a manner similar to the way of task placing at the Kanban task board in software development. Initially each inventory card represents a certain amount of raw material. The columns of the Kanban task board represent all stages of the manufacturing process. The final column contains the products that are ready to be delivered to the customer.

As we have already mentioned, the Kanban method is based on two main principles: visualization of workflow, and limitation of work in progress. The Kanban task board allows the managers to visualize the inventory process. If they see that there is too much inventory cards on the task board, they may limit their amount. For the enterprise that means that the work on certain consignment should be suspended. In most cases that helps to avoid unnecessary production and make the enterprise profitable.