How Kanban System Works

Kanban is a popular project management system. It was invented in Japan in the late 1940s. The method has been significantly upgraded since those days, but its main principles are the same:

- Consideration of the customer’s demand;

- Visualization of workflow;

- Limitation of the work in progress.

Any modern Kanban project is based on these principles. However, there are lots of people who want to know how Kanban system works. This article was written for them.

If we want to describe how Kanban works, the first thing we should mention is that it is based on customer demands. It means that any company that has implemented Kanban must learn the customer requests before starting the manufacturing of a new product. That is the best way to satisfy the clients. Of course, such type of project management is related to some difficulties, but the result is worth of it. The customers prefer to buy products they really need.

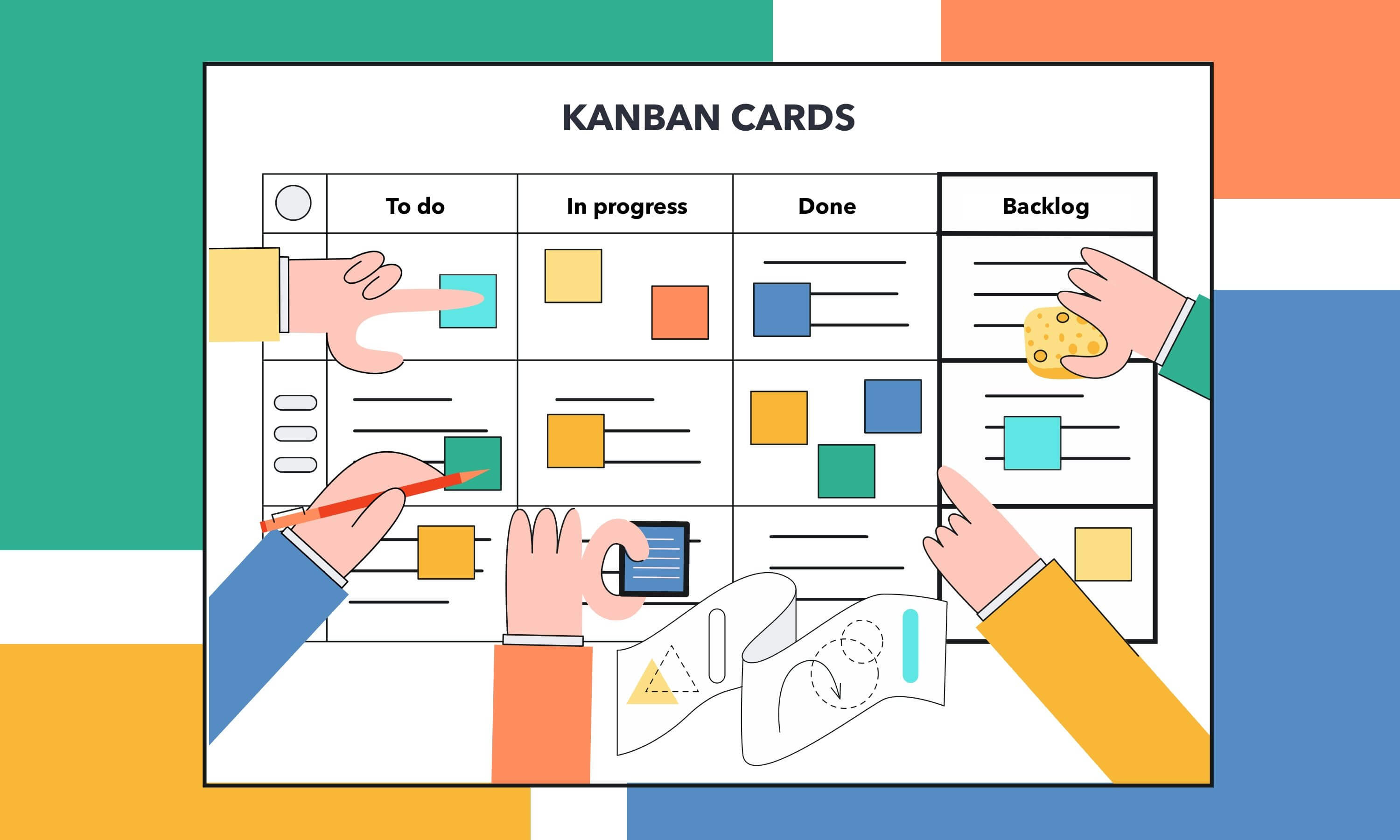

Any company that manages its projects in Kanban style uses Kanban boards. A Kanban task board is a simple device that looks like a table subdivided into several columns. Each column reflects a certain stage of work. The tasks are usually depicted as special cards.

How do Kanban cards work?

Kanban cards are usually placed on the Kanban task board in accordance with the stage of their performance. As the task runs into the process of manufacturing, it enters the first column of the task board. After that it moves through all columns until it is finished. Then it is placed in the column “done”. That means that it is ready to delivery.

The most important issue in the work of any Kanban system is to limit the amount of WIP units. If you have too much work in progress, you risk decreasing the quality of your product. That is why it is extremely important to process only several tasks at the same time. Sometimes even one task is enough.