Kanban Quick Start Guide: 3 Key Principles of Kanban

Kanban project management system is extremely popular today. It is used by various companies all over the world. The system can be applied to any industry. Perhaps that is the main reason for its popularity. Many specialists all over the world are trying to find the proper Kanban definition. We will also try to do that in this article. But before giving the definition of kanban system it is necessary to say a few words about its history and functional features.

Kanban was originated in the late 1940s in Japan. At that time a famous corporation Toyota had lots of problems with the delivery of its production. The managers of the company decided to invent a new project management system that should have allowed them to improve the quality of production and the terms of delivery. The system was called Kanban. It was based on three main principles.

The first principle of Kanban is consideration of the customer’s demands. All companies that use Kanban follow this principle. It allows them to avoid unnecessary production. The manufacturing process requires lots of raw material. It means that every successful enterprise should manufacture only the products that are required in the market. This strategy is simple, but it is the way to success.

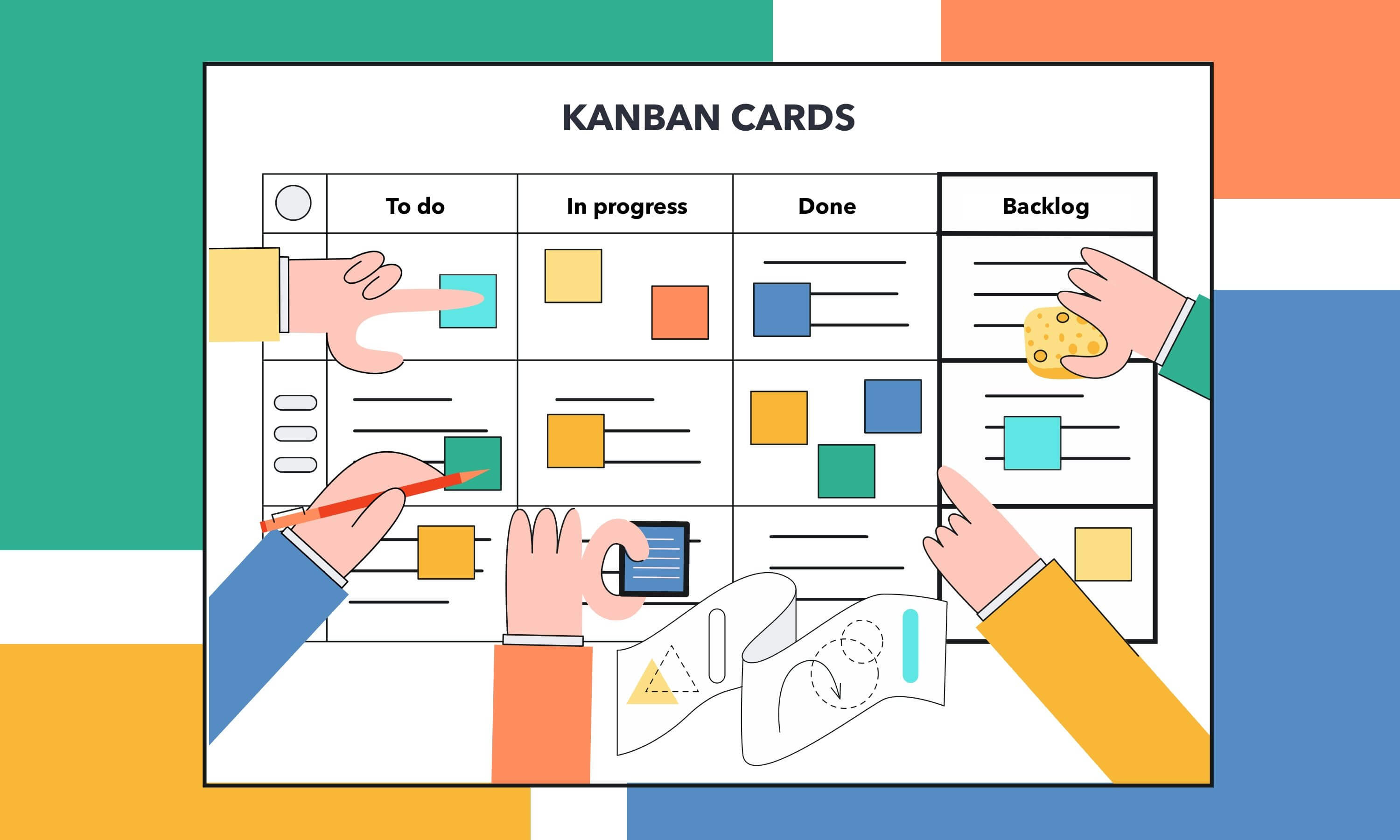

Workflow visualization is the second principle of Kanban system. It is based on the use of a special device called the Kanban board. It is actually a table with several columns. Each column represents a certain stage of the manufacturing process. Every task should pass all these stages before it is done. The tasks are placed on the Kanban board in accordance with the stage of their performance. As a result, the managers can see the progress of their work and make some corrections in it if it is necessary.

The third principle of Kanban system is based on the limitation of work in progress. The idea is simple: the enterprise cannot perform too many tasks at the same time. It is necessary to limit the amount of work in progress to improve the quality of the final product and the terms of delivery.

Definition of Kanban system

Now, as we know the history of Kanban and its main principles, we can formulate the definition of Kanban system.

Kanban is a project management system designed to improve the quality of production and the terms of its delivery. This simple definition fully describes the nature of Kanban. However, it has lots of aspects that cannot be described in several phrases or even in one article. The issue is that Kanban applies to many different industries. It may have lots of specific features that depend on the enterprise where it is implemented.

In software development, Kanban is a popular Agile methodology. It is characterized by strong customer involvement into the process of product development. Like other enterprises that use Kanban, software development companies have Kanban task boards to visualize the workflow of their teams. Today there are lots of Kanban project management tools for software developers. They allow the teams to simplify their work and improve the terms of product delivery.